Many customers ask about the difference between tanks made by blow molding and tanks made by roto molding, and we have also heard some opinions in the market that roto tanks are better. That is why, today we wanted to explain the differences to you in a scientific and professional way through the experience of Sawab engineers.

What is roto and blow molding?

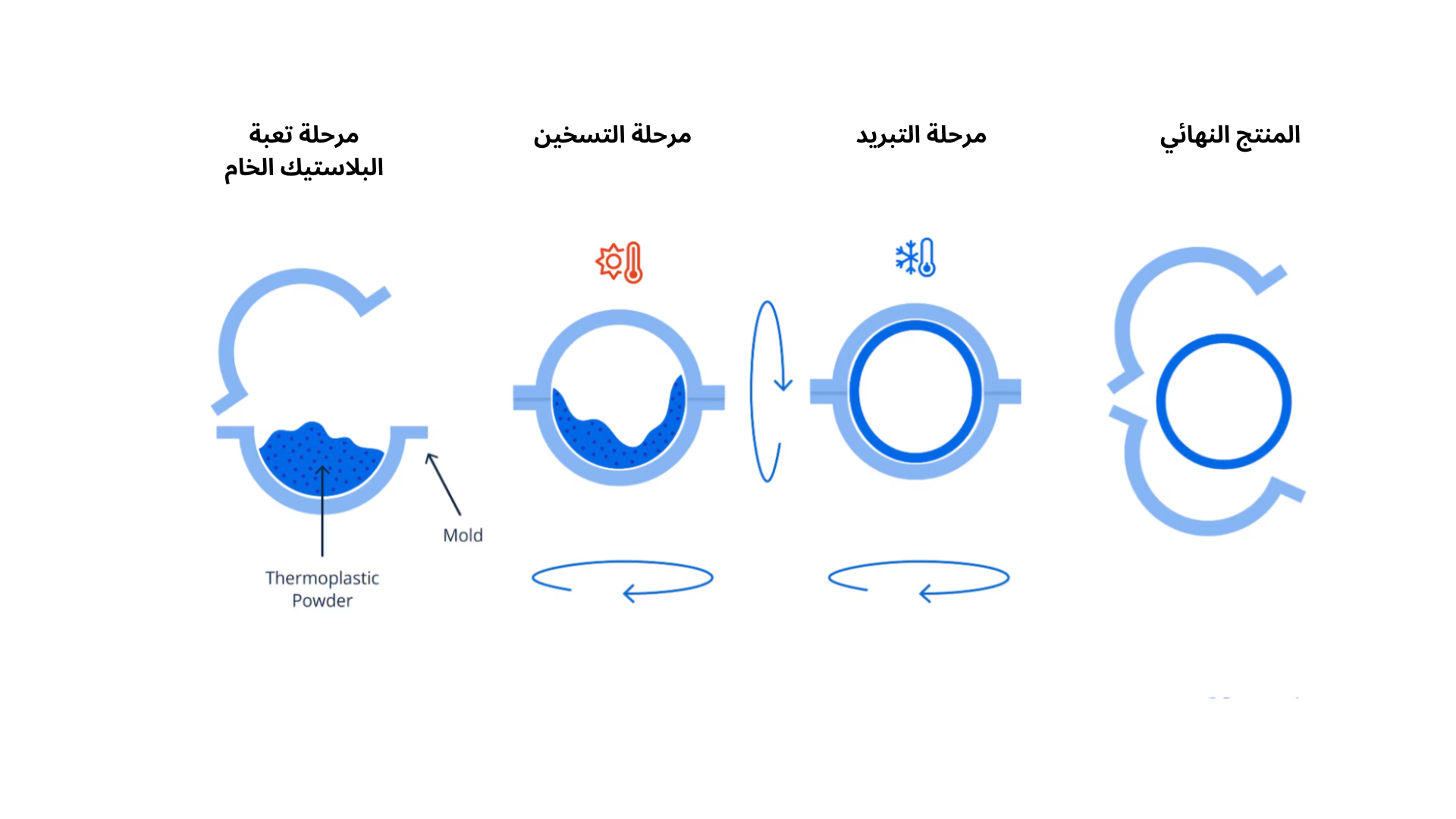

- Roto (rotational molding) : This method depends on pouring the plastic inside the tank mold, and we usually use a larger quantity of plastic.

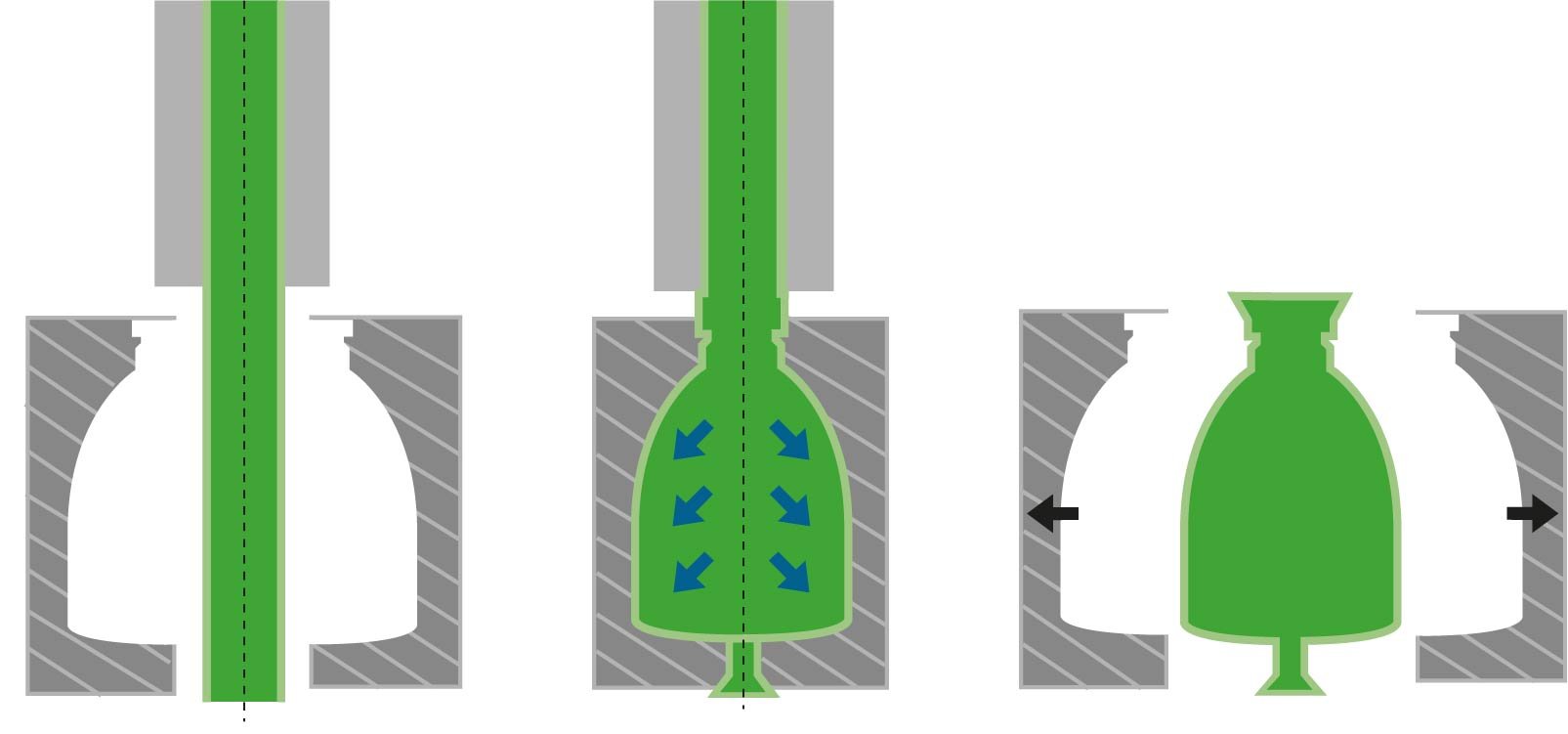

- Blow molding : In this technique, the plastic is heated to a certain temperature before air is blown into the mold to form the tank. Although the amount of plastic used is less, the advanced plastic blends used ensure excellent resistance to cracking and damage.

Which is better?

Both methods offer excellent quality, with good insulation and quality assurance, but choosing the best one depends largely on the manufacturer and the quality of the materials.

What distinguishes the blow tanks is that they are lighter and more economical, thanks to the use of less plastic without compromising on quality. In addition, the blowing technology relies on advanced plastic compounds that ensure high durability of the tank.

At Sawab, we are keen to choose the best manufacturers who have quality certificates from the Saudi Standards, Metrology and Quality Organization. In addition, we pay great attention to after-sales services, warranty and fast delivery, to ensure peace of mind with every order.

Order your tank now from "Sawwab" and relax!